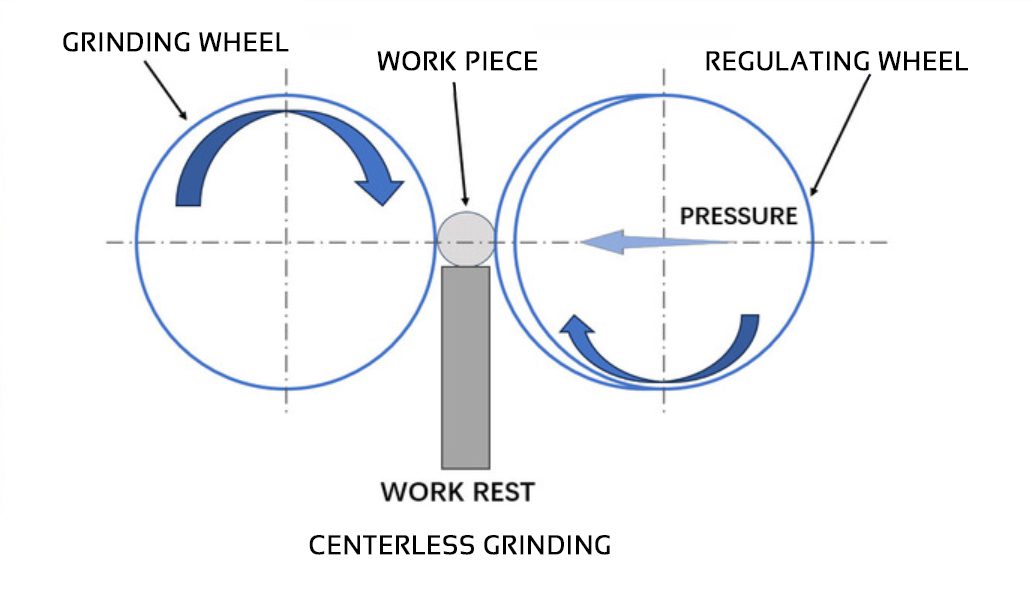

Centerless Grinding

With centerless grinding, tubing is placed on a work rest that positions the tube between a regulating wheel that spins the tube in one direction, and a grinding wheel that spins in the opposite direction. By varying the distance between the wheels, very precise diameter control and smoothing of even the roughest extruded outer surface conditions can be achieved.

We offer:

- Thru-feed grinding: where the entire length of tubing is finished on the grinder

- In-feed grinding: creates a smooth surface and decreases the diameter on one or both ends of the tube. Tapered, stepped, or end grind can be utilized for ease in adding fittings and other components.

- Dimensional tolerances held to within +/- 0.0005” or better

Parylene

Parylene coating provides a slippery, easily cleaned finished surface. Our custom-coating operation can apply a permanently bonded uniform film of 1µm thickness (or otherwise as specified). Applied by our skilled technicians this silky surface keeps products like tubing and wire from tangling or tugging on skin, hair or fabric. It does not attract debris and is far easier to clean than uncoated soft TPE plastic.

The parylene grade used at New England Tubing offers optimum lubricity compared to other options, and is an inert, biocompatible dry lubricant that resists heat, radiation, solvents, fungus and bacteria growth. The coating is bonded to the catheters or cable’s outer layer, and at 1 µm, it adds virtually nothing to final dimensions.

Performance Characteristics and Custom Design Options

- Low friction (comfortable, ergonomic surface)

- Biocompatible / inert transparent polymer

- Sterilization / Autoclave stable

- Extremely thin, no build to jacket OD

- Crisp masked edges allow for durably bonded connections

- Custom masking and thickness specifications readily incorporated into our process