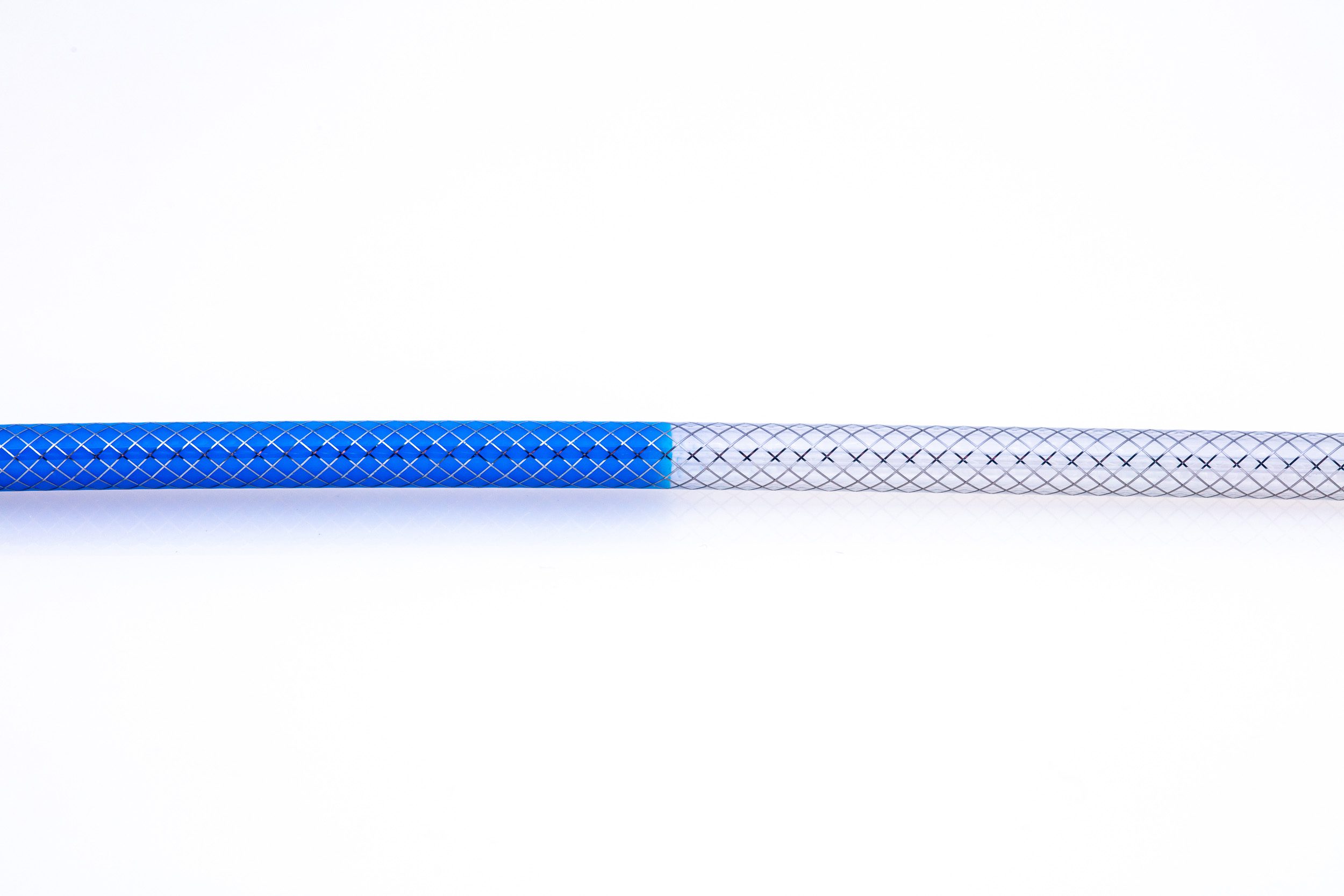

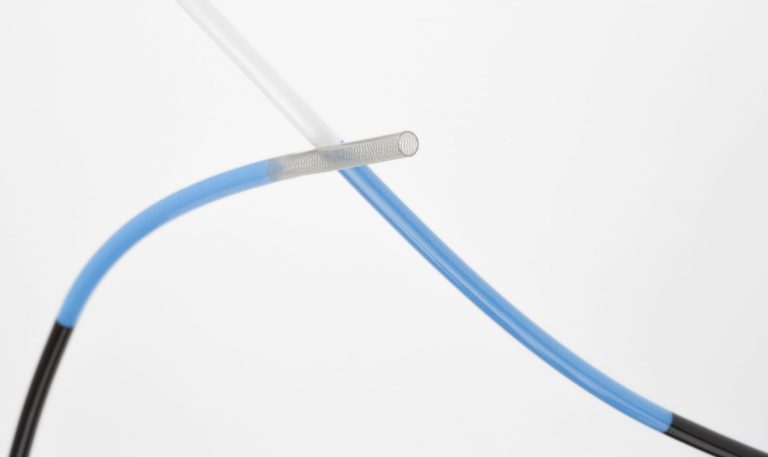

New England Tubing’s comprehensive extrusion expertise combined with advanced assembly capabilities, enable the production of reinforced, multi-durometer custom tubing solutions. By manufacturing tubing with distinct durometer zones and integrating stainless-steel braids or spiral reinforcements, we can precisely tailor kink resistance, flexibility, and torque response along the length of a single component. Typically, the proximal section is engineered with a higher durometer material to support insertion and positioning, while a more flexible distal section enhances navigation through complex anatomical pathways. When paired with braid reinforcement, this approach produces tubing that maintains a stiff body section and a highly flexible distal segment—without compromising critical performance characteristics such as torque transmission, kink resistance, and hoop strength.

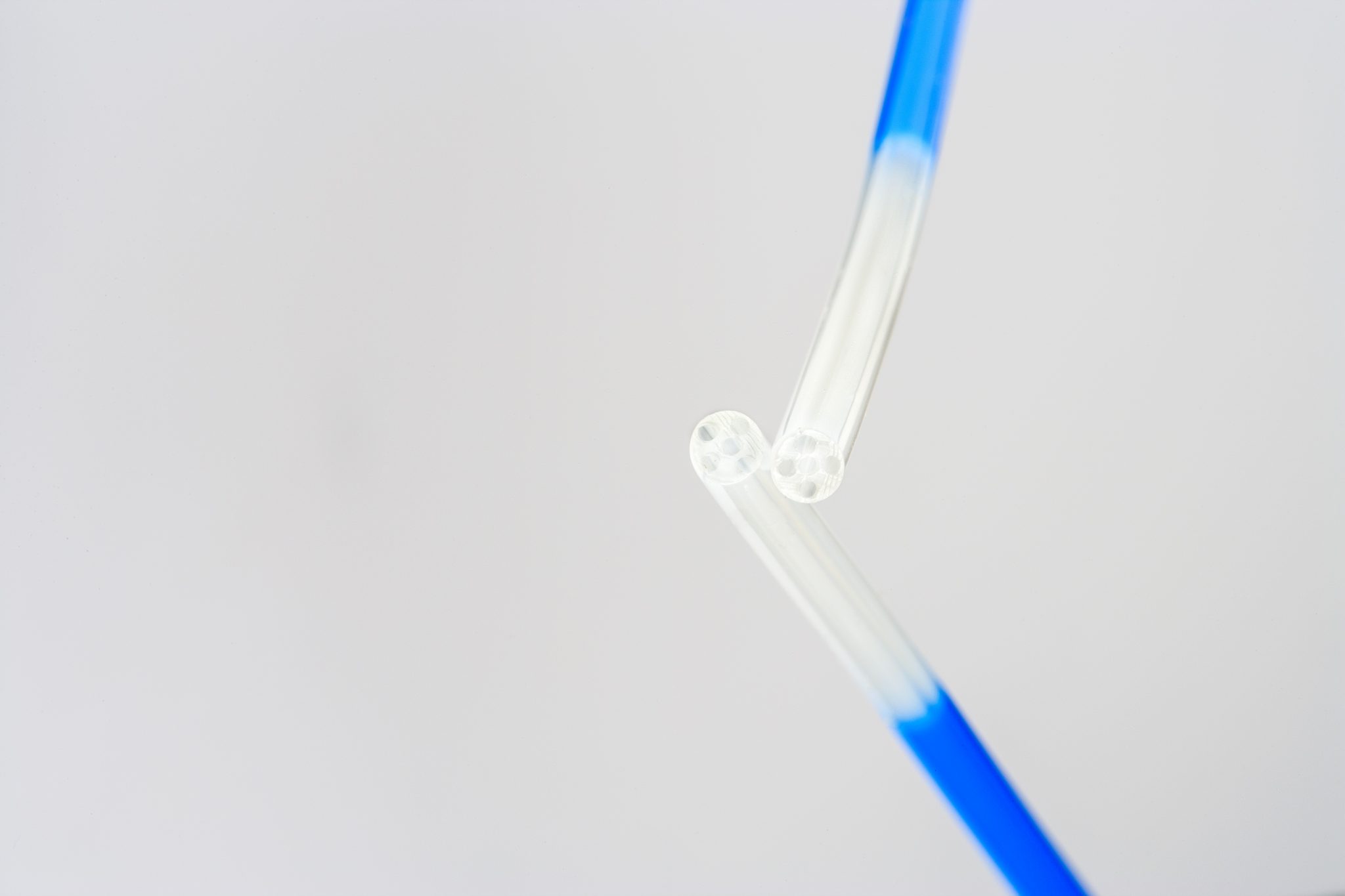

Custom multi-durometer tubing can be designed in single- or multi-lumen configurations, with or without reinforcement. Reinforced designs typically feature a continuous inner liner, continuous reinforcement layer, and an outer layer where durometer transitions occur. Additionally, radiopaque polymer can be added during assembly to use as marker bands. Further customization over shaft performance can be achieved by varying braid or spiral density along the length, further refining flexibility profiles. Longitudinal members may also be incorporated to enhance tensile strength and column strength, supporting demanding clinical and mechanical requirements.

Size Range

0.025” – 0.250” (0.635 mm – 6.35 mm) depending on design