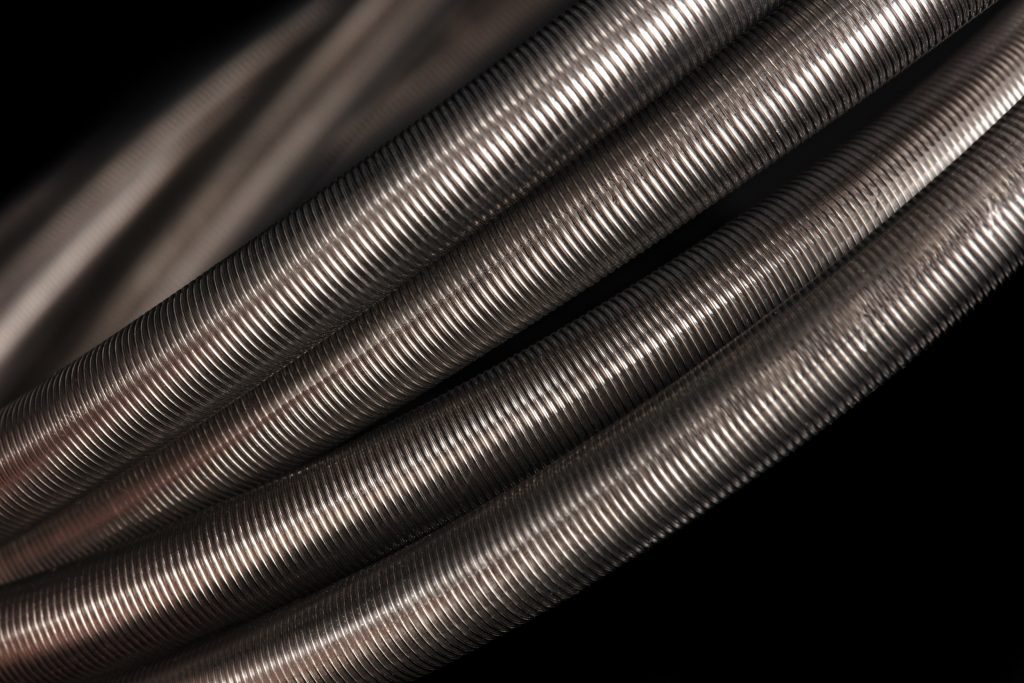

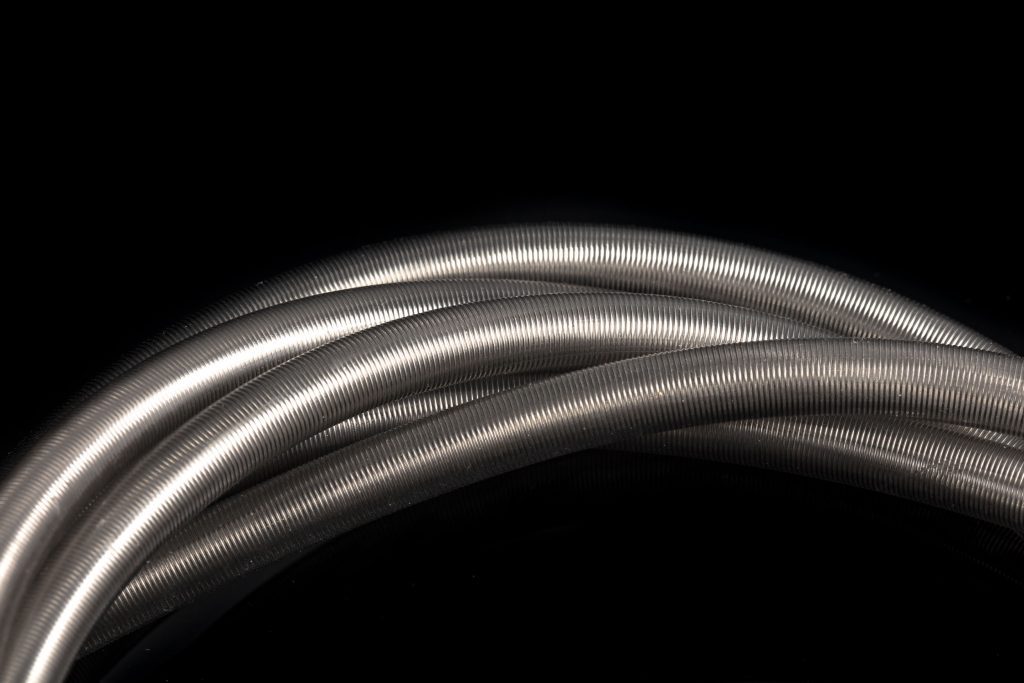

New England Tubing specializes in spiral reinforced tubing, typically used to improve hoop (crush) strength and provide kink resistance. Our in-house technical staff has designed and built our PLC controlled high speed spiral winders, capable of handling a wide range of tubes and sizes. Whether miniature tubing for neurological applications or larger endoscopy tubes for gastrological procedures, we have the manufacturing expertise for your project. Need something even more custom? We also have the ability to change the density of the spiral over a span, providing varied levels of flexibility and performance along the discreet tube length.

As with braid reinforced tubes, New England Tubing can add a longitudinal member to a spiral reinforced tube which again modifies its tensile and elongation properties. Our team has experience with a wide array of materials used for spiral reinforcing ranging from flat or round stainless steel alloys to high strength monofilament polymers.

Size Range

0.025” – 0.750” (0.66 mm – 19.05 mm) depending on design

Spiral Reinforced Materials

- Round Wire (from as 0.001” [0.025 mm])

- Flat Wire (from as 0.0003” x 0.002” [0.0076 mm x 0.051 mm])

- Stainless Steel

- Copper and Copper Alloys

- Nitinol

- Textiles

- High Strength Polymers

Benefits of Spiral Reinforcement

- Kink Resistance

- Variable Flexibility

- Improved Hoop (Crush) Strength

- Aides in Increased Column Strength

- Adds Less Build than Braid Reinforcement

- Less Impact on Flexibility than Braid Reinforcement