Tipping

Used to aid in the insertion and guidance of devices such as catheters and introducers.

Tapered tips, rounded ends, specific tip geometries, radiused, low-profile, atraumatic, and radiopaque ends can be added to aid in the insertion and guidance of devices.

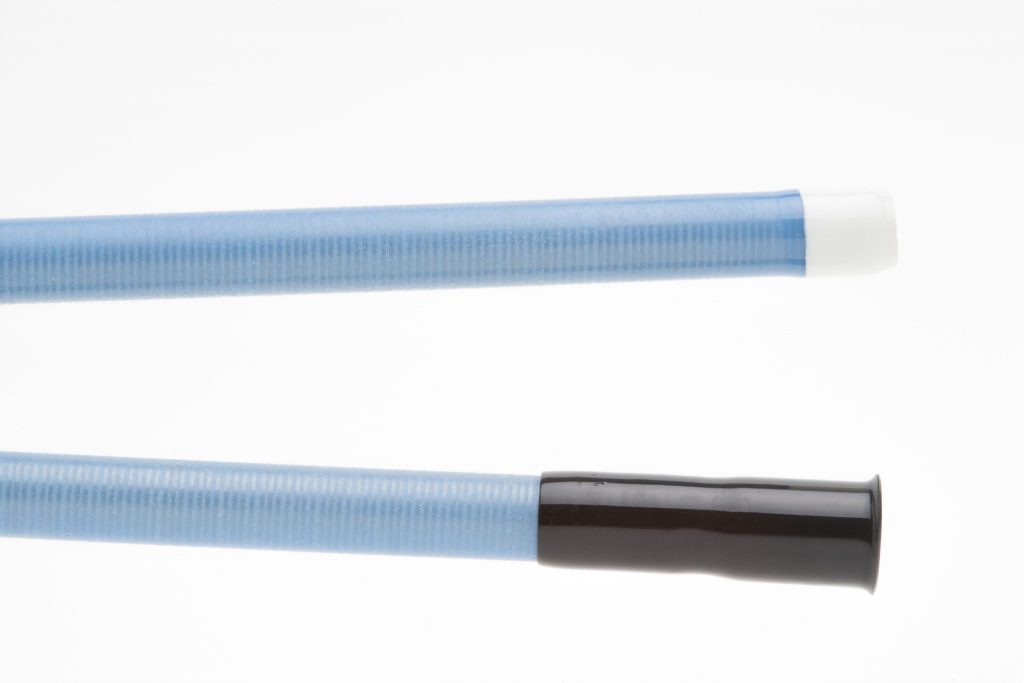

Hubbing/Flaring

Used to expand the OD of the tube up to 1.4 times the beginning OD.

Improves accessibility of the interior of the tubing to facilitate insertion of tools, stents, wire, fluids, etc. allowing easy integration into complex systems.

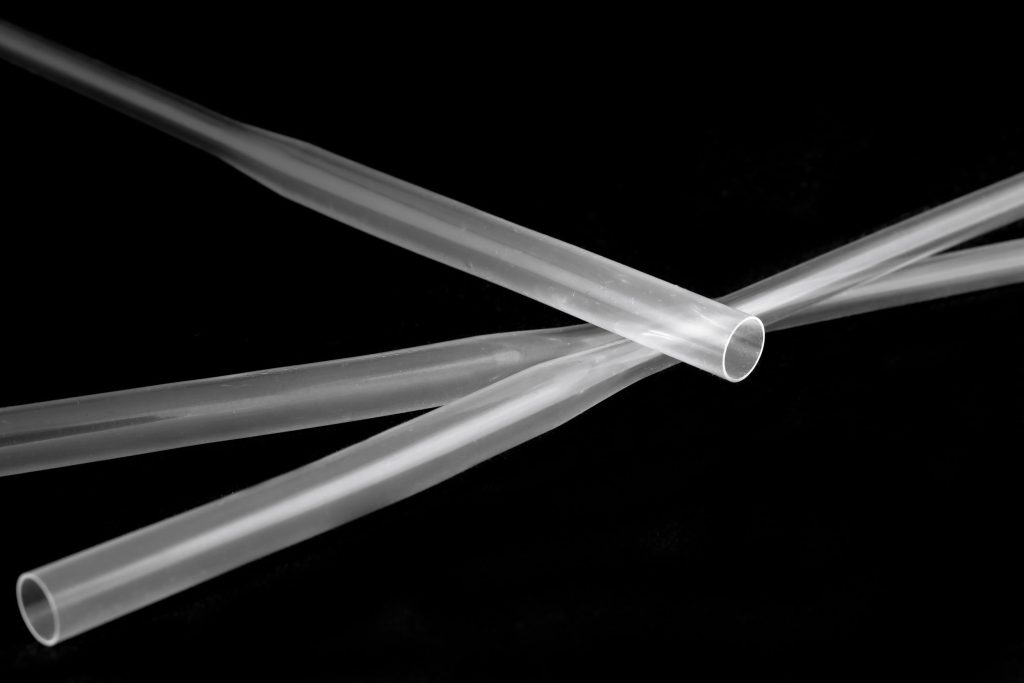

Cones/Neckdowns

Tapers or expands the ID or OD along the tube length.

Thermal Forming

Tubes can be molded to hold a required shape for placement in constrained spaces or easing assembly applications.

May be formed with single or multiple elbows, curves, twists, and pigtails or coils.

Extruded Tube Annealing

Annealing uses a stress relieving cycle to straighten and enhance the mechanical properties of the tube by relieving any internal stresses that may result from the manufacturing process.

New England Tubing uses a precisely controlled and calibrated annealing oven to straighten both reinforced and unreinforced tubing products. This oven is capable of straightening parts up to 100 inches in length and annealing processes of up to 500°F (260°C).